- Services

- 3D CAD Services

- CNC Forming Services

- CNC HD Plasma Cutting Services

- CNC Punching Services

- CNC Machining Services

- CNC Laser Cutting Services

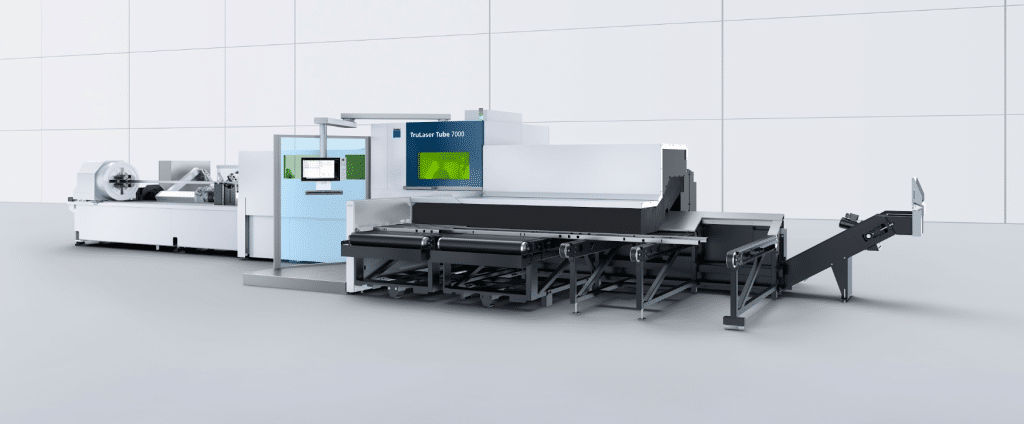

- Tube Laser Cutting Services

- MIG & TIG Welding and Fabrication Services

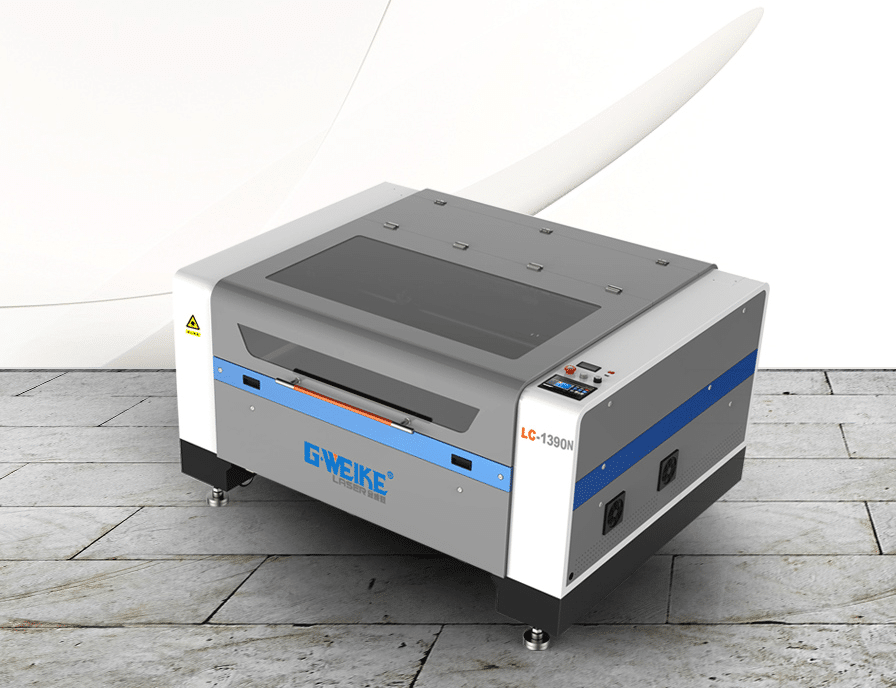

Laser Cutting

Highlighting our sheet metal processing capabilities are our CNC laser cutters.CNC Forming

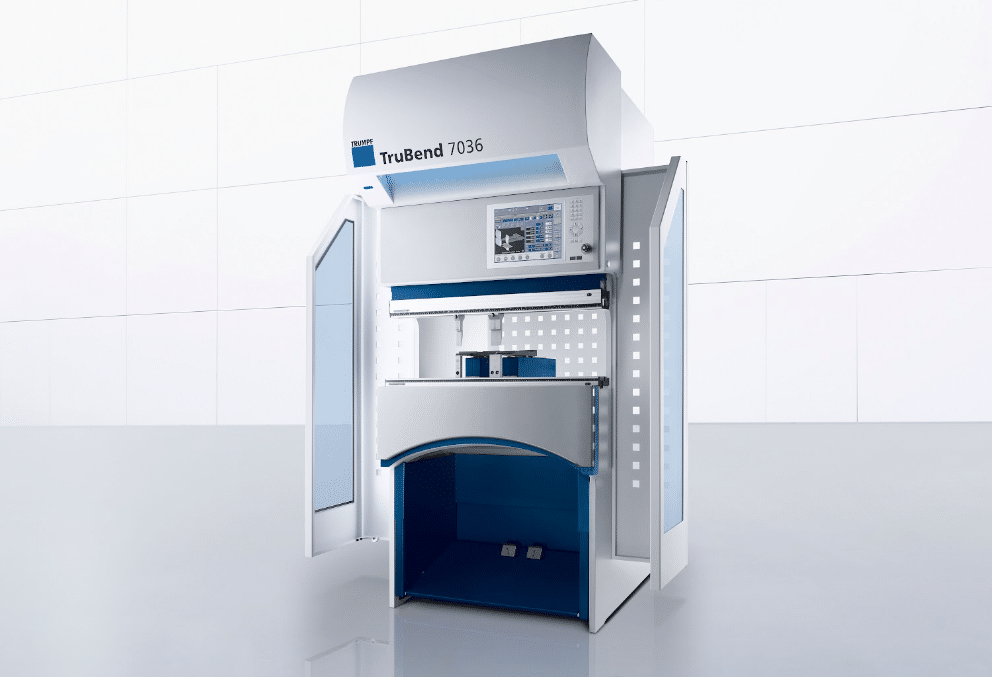

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

3D CAD

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

Welding & Fabrication

MillerMetal offers in-house MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

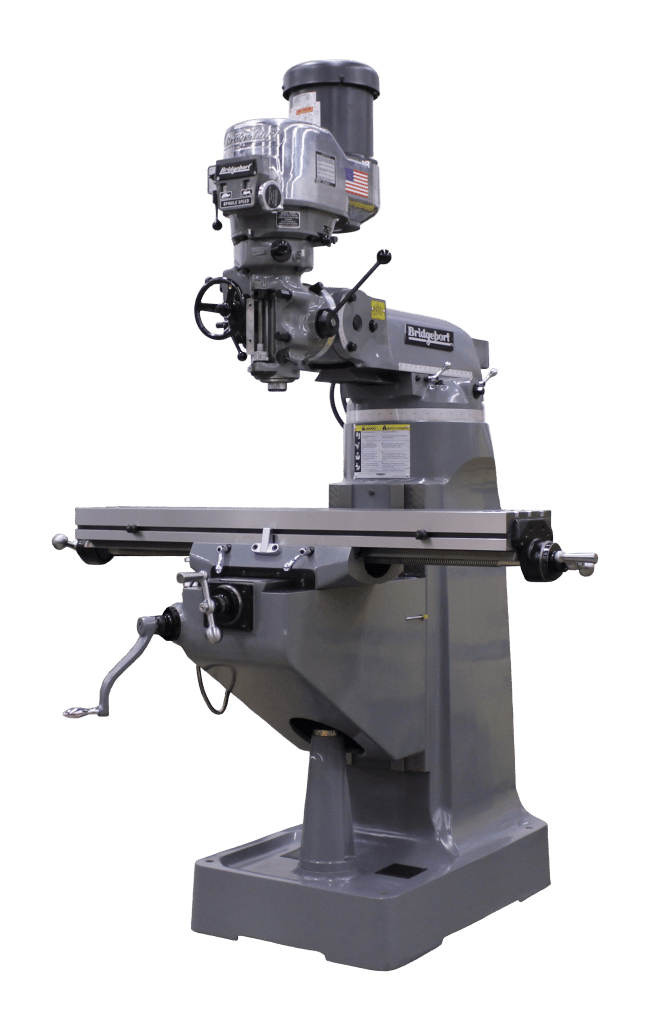

Machining

Rounding out our ability to offer turnkey products, MillerMetal offers a wide range of CNC machining services.

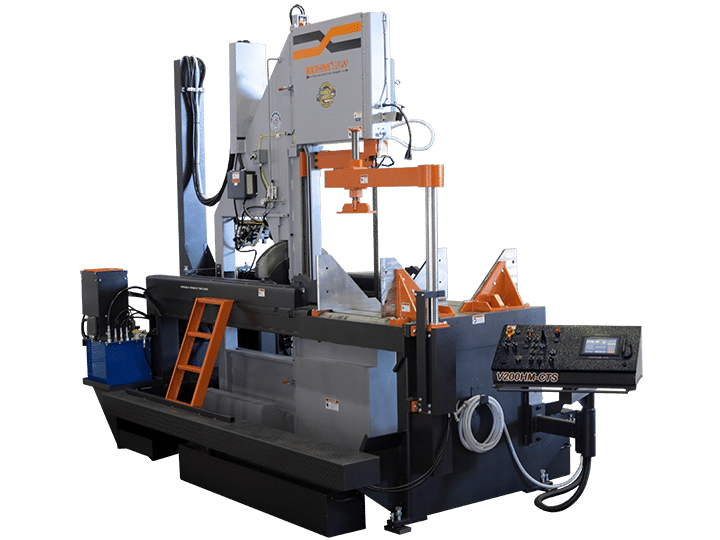

CNC HD Plasma Cutting

As an alternative to sheet and plate cutting, Miller Metal offers CNC HD Plasma cutting for parts with non-critical dimensions.

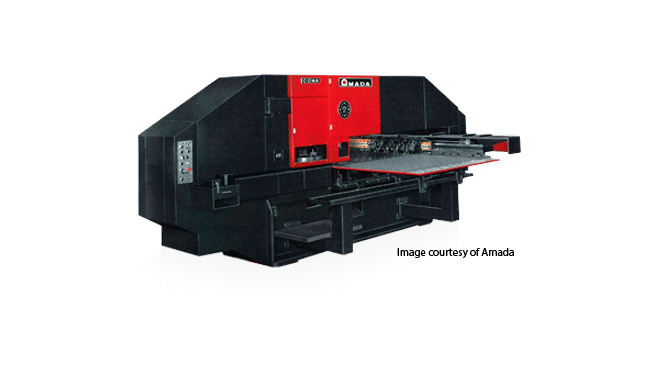

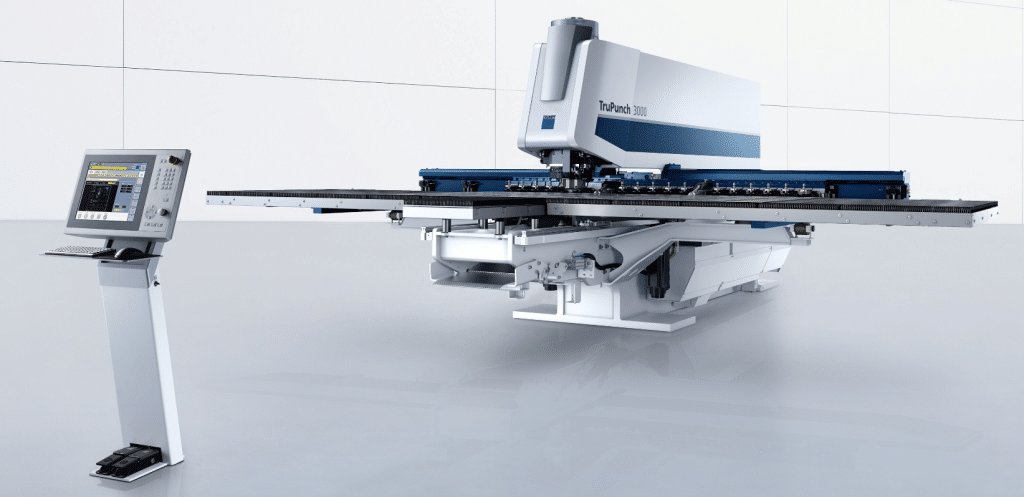

CNC Punching

For years, MillerMetal has offered CNC punching as an affordable way to process sheet metal.

Tube Laser

Our state-of-the art tube laser is on the cutting edge (literally)! Its swiveling head makes easy work out of complex weldment miters and coping.

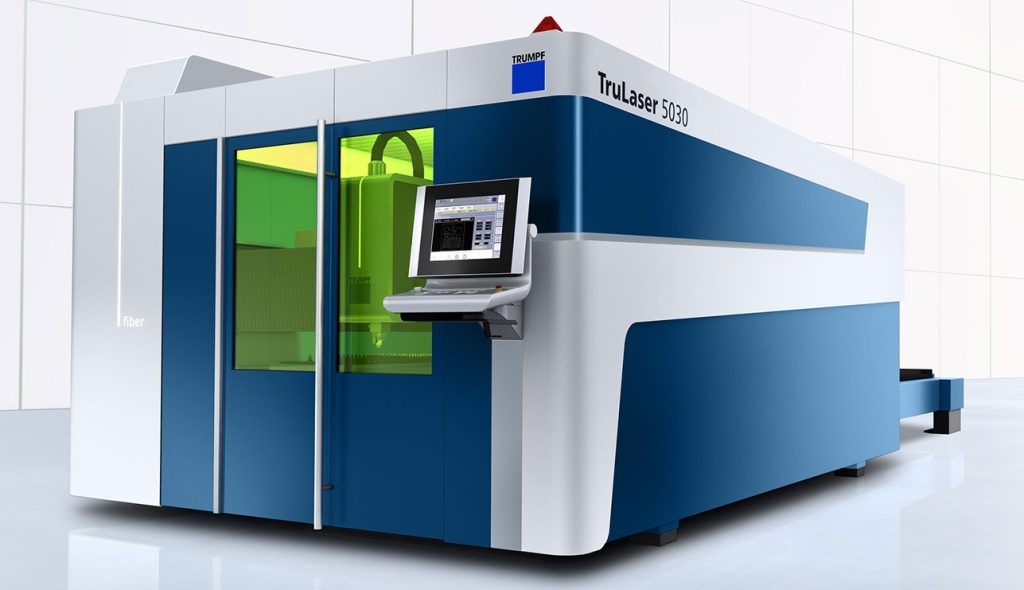

2 Trumpf TruLaser 5030 Fiber Lasers

The TruLaser 5030 fiber, impress with their high processing speed….

Trumpf TruLaser 5040 Fiber Laser

The TruLaser 5040 fiber, impress with their high processing speed….

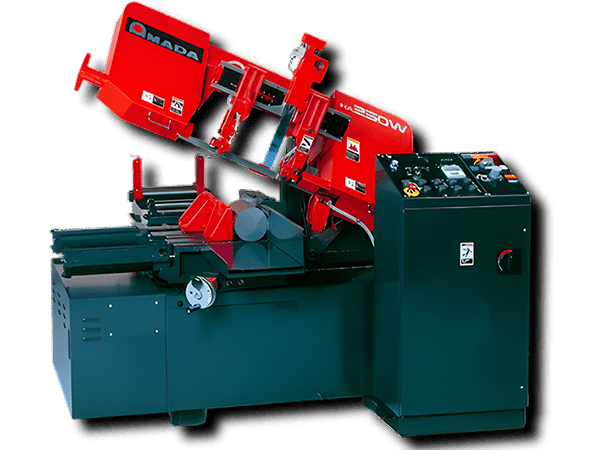

- Our Equipment

- CNC Cutting Equipment

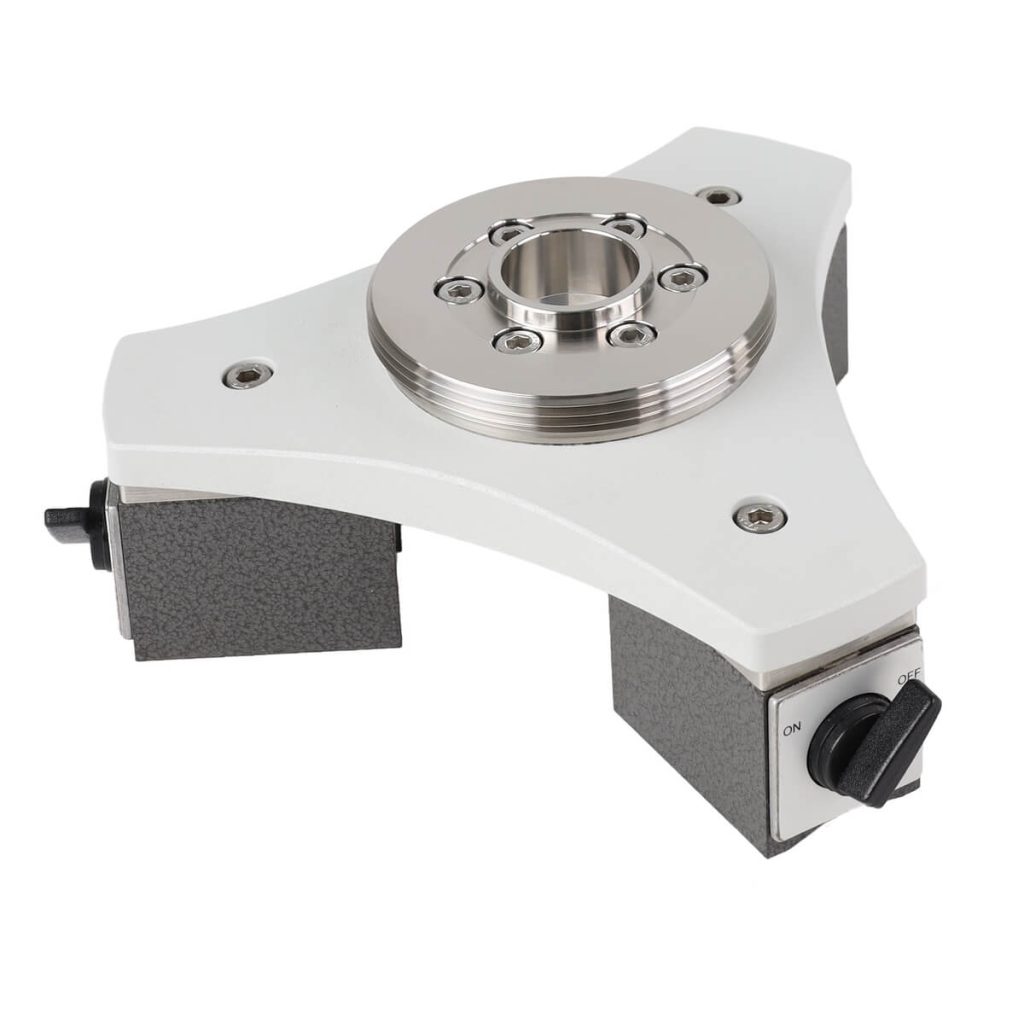

- CNC Forming Equipment

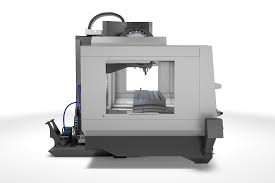

- CNC Machining Equipment

- MIG & TIG Welding Equipment

- Miscellaneous Equipment

CNC Cutting

Highlighting our sheet metal processing capabilities are our CNC plasma equipment.

FORMING

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

Lasers

MillerMetal offers high-speed, precision cuts for sheet metal and tubes using advanced CNC laser cutters.

MACHINING

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

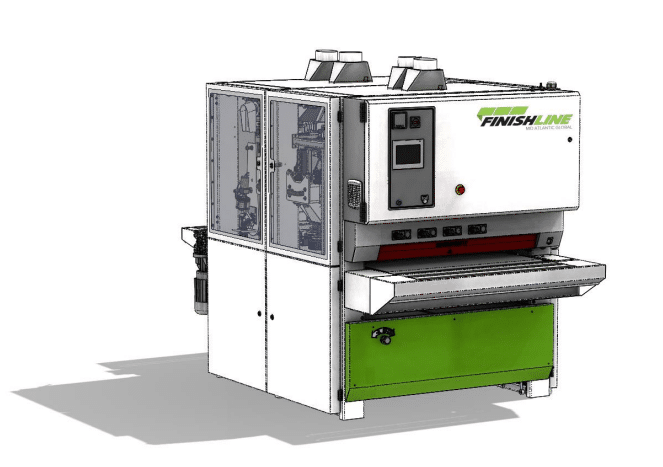

CNC Punch Press

Fast punching with enhanced flexibility for varied metal parts.

WELDING

MillerMetal offers in-house Robotic welding, as well as MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

MISC

Miller Metal provides CNC cutting for parts that do not require tight dimensional tolerances.

- About Us

- Contact Us

302-337-2291

302-337-2291

- Services

- 3D CAD Services

- CNC Forming Services

- CNC HD Plasma Cutting Services

- CNC Punching Services

- CNC Machining Services

- CNC Laser Cutting Services

- Tube Laser Cutting Services

- MIG & TIG Welding and Fabrication Services

Laser Cutting

Highlighting our sheet metal processing capabilities are our CNC laser cutters.CNC Forming

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

3D CAD

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

Welding & Fabrication

MillerMetal offers in-house MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Machining

Rounding out our ability to offer turnkey products, MillerMetal offers a wide range of CNC machining services.

CNC HD Plasma Cutting

As an alternative to sheet and plate cutting, Miller Metal offers CNC HD Plasma cutting for parts with non-critical dimensions.

CNC Punching

For years, MillerMetal has offered CNC punching as an affordable way to process sheet metal.

Tube Laser

Our state-of-the art tube laser is on the cutting edge (literally)! Its swiveling head makes easy work out of complex weldment miters and coping.

2 Trumpf TruLaser 5030 Fiber Lasers

The TruLaser 5030 fiber, impress with their high processing speed….

Trumpf TruLaser 5040 Fiber Laser

The TruLaser 5040 fiber, impress with their high processing speed….

- Our Equipment

- CNC Cutting Equipment

- CNC Forming Equipment

- CNC Machining Equipment

- MIG & TIG Welding Equipment

- Miscellaneous Equipment

CNC Cutting

Highlighting our sheet metal processing capabilities are our CNC plasma equipment.

FORMING

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

Lasers

MillerMetal offers high-speed, precision cuts for sheet metal and tubes using advanced CNC laser cutters.

MACHINING

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

CNC Punch Press

Fast punching with enhanced flexibility for varied metal parts.

WELDING

MillerMetal offers in-house Robotic welding, as well as MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

MISC

Miller Metal provides CNC cutting for parts that do not require tight dimensional tolerances.

- About Us

- Contact Us