Specifications

| Max Profile Length | 60′ |

| Max Profile Height | 48″ |

| Spindle Speed | 3,000 RPM |

| Motor | 25 HP |

| Max X-axis Speed | 150’/min |

| Max Y-Axis Speed | 60’/min |

| Control | Siemens 840D CNC |

| Tool Changer | 8 Station |

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

MillerMetal offers in-house MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Rounding out our ability to offer turnkey products, MillerMetal offers a wide range of CNC machining services.

As an alternative to sheet and plate cutting, Miller Metal offers CNC HD Plasma cutting for parts with non-critical dimensions.

For years, MillerMetal has offered CNC punching as an affordable way to process sheet metal.

Our state-of-the art tube laser is on the cutting edge (literally)! Its swiveling head makes easy work out of complex weldment miters and coping.

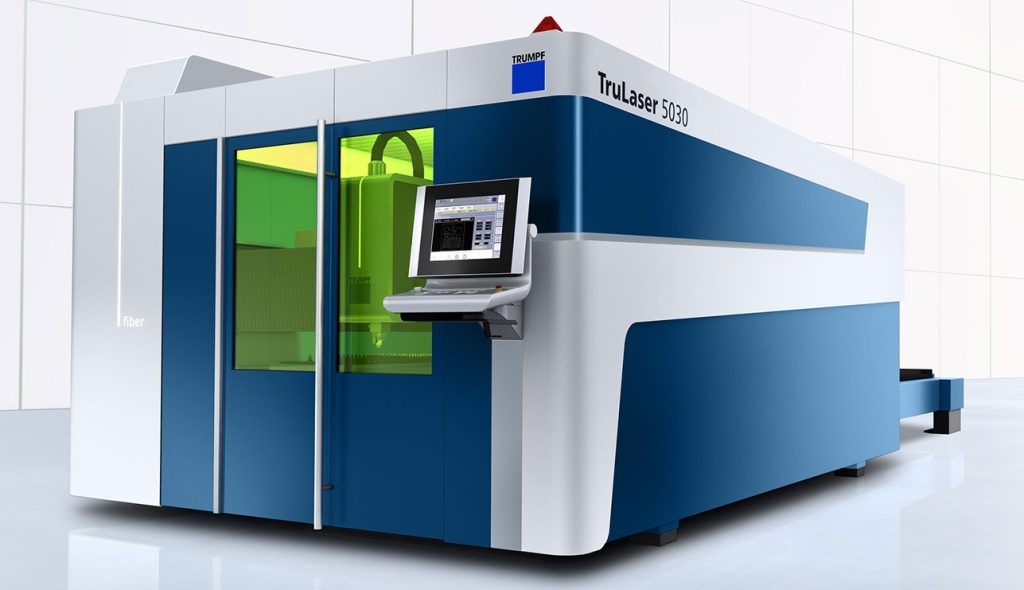

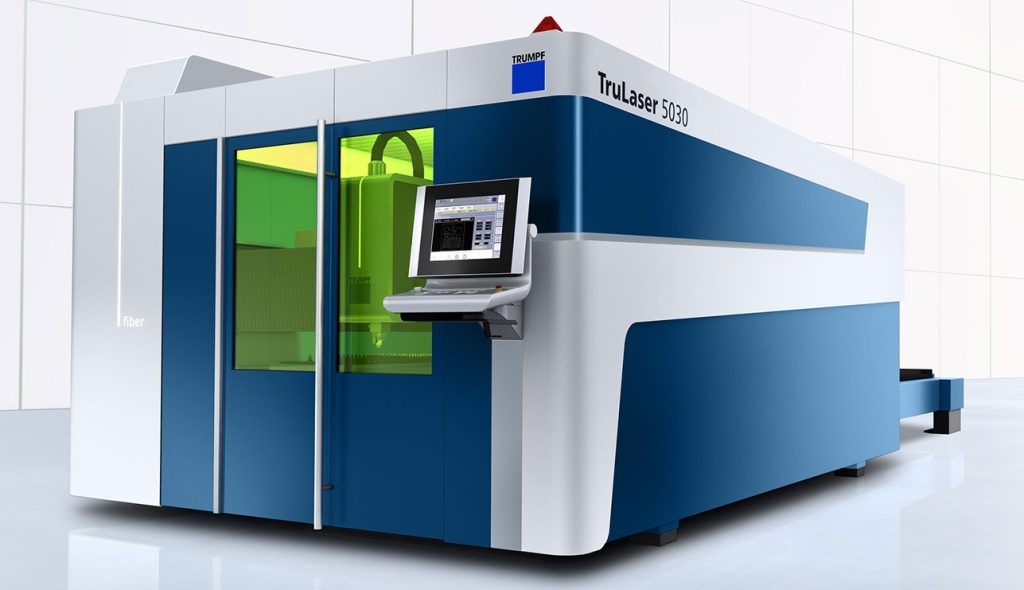

The TruLaser 5030 fiber, impress with their high processing speed….

The TruLaser 5040 fiber, impress with their high processing speed….

Highlighting our sheet metal processing capabilities are our CNC plasma equipment.

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

MillerMetal offers high-speed, precision cuts for sheet metal and tubes using advanced CNC laser cutters.

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

Fast punching with enhanced flexibility for varied metal parts.

MillerMetal offers in-house Robotic welding, as well as MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Miller Metal provides CNC cutting for parts that do not require tight dimensional tolerances.

302-337-2291

302-337-2291

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

MillerMetal offers in-house MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Rounding out our ability to offer turnkey products, MillerMetal offers a wide range of CNC machining services.

As an alternative to sheet and plate cutting, Miller Metal offers CNC HD Plasma cutting for parts with non-critical dimensions.

For years, MillerMetal has offered CNC punching as an affordable way to process sheet metal.

Our state-of-the art tube laser is on the cutting edge (literally)! Its swiveling head makes easy work out of complex weldment miters and coping.

The TruLaser 5030 fiber, impress with their high processing speed….

The TruLaser 5040 fiber, impress with their high processing speed….

Highlighting our sheet metal processing capabilities are our CNC plasma equipment.

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

MillerMetal offers high-speed, precision cuts for sheet metal and tubes using advanced CNC laser cutters.

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

Fast punching with enhanced flexibility for varied metal parts.

MillerMetal offers in-house Robotic welding, as well as MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Miller Metal provides CNC cutting for parts that do not require tight dimensional tolerances.

The BDL-1250/9D, with its superior clamping power for carbide drilling, features an impressive 1800 RPM spindle speed. We have crafted the industry’s premier beam drill line by incorporating modern technologies like micro-mist coolant, spindle-specific motors, carbide part marking, Break-Through Detection technology, and automatically adjusting roller measurement.

Developed by Peddinghaus, Raptor 3D CAD/CAM Software furthers CNC innovation by enabling users to program faster and more accurately. Inspect, modify, and export part information directly within the 3D platform. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators.

| Max Profile Length | 60′ |

| Max Profile Height | 48″ |

| Spindle Speed | 3,000 RPM |

| Motor | 25 HP |

| Max X-axis Speed | 150’/min |

| Max Y-Axis Speed | 60’/min |

| Control | Siemens 840D CNC |

| Tool Changer | 8 Station |

We manage the logistical chain to maintain high levels of efficiency by decreasing inventory investment and simplifying production control.

MillerMetal Fabrication is uniquely suited to assisting your business in meeting the challenges of the 21st century.

We are committed to flawless execution and delivery, and we take pride in helping our customers thrive in today’s challenging environment. We share the visions of our customers, and our commitment to adding the most value for the lowest cost.

Thank you for your interest in MillerMetal Fabrication. Please contact us using the information below. For additional information on our industry expertise, please visit the appropriate page on our site.

Mon-Fri 8AM-4:30PM