- Services

- 3D CAD Services

- CNC Forming Services

- CNC HD Plasma Cutting Services

- CNC Punching Services

- CNC Machining Services

- CNC Laser Cutting Services

- Tube Laser Cutting Services

- MIG & TIG Welding and Fabrication Services

Laser Cutting

Highlighting our sheet metal processing capabilities are our CNC laser cutters.CNC Forming

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

3D CAD

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

Welding & Fabrication

MillerMetal offers in-house MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Machining

Rounding out our ability to offer turnkey products, MillerMetal offers a wide range of CNC machining services.

CNC HD Plasma Cutting

As an alternative to sheet and plate cutting, Miller Metal offers CNC HD Plasma cutting for parts with non-critical dimensions.

CNC Punching

For years, MillerMetal has offered CNC punching as an affordable way to process sheet metal.

Tube Laser

Our state-of-the art tube laser is on the cutting edge (literally)! Its swiveling head makes easy work out of complex weldment miters and coping.

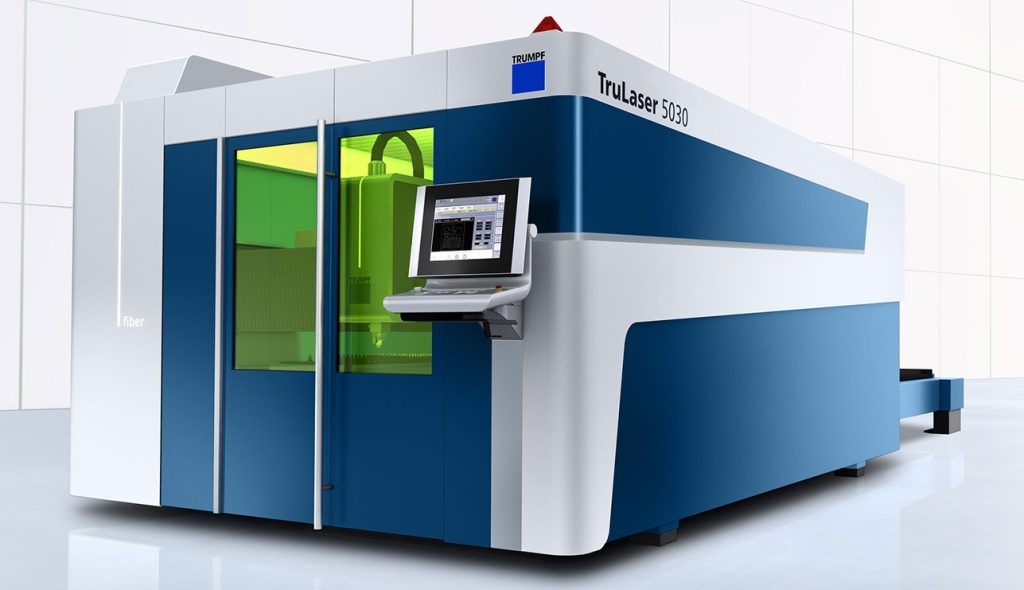

2 Trumpf TruLaser 5030 Fiber Lasers

The TruLaser 5030 fiber, impress with their high processing speed….

Trumpf TruLaser 5040 Fiber Laser

The TruLaser 5040 fiber, impress with their high processing speed….

- Our Equipment

- CNC Cutting Equipment

- CNC Forming Equipment

- CNC Machining Equipment

- MIG & TIG Welding Equipment

- Miscellaneous Equipment

CNC Cutting

Highlighting our sheet metal processing capabilities are our CNC plasma equipment.

FORMING

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

Lasers

MillerMetal offers high-speed, precision cuts for sheet metal and tubes using advanced CNC laser cutters.

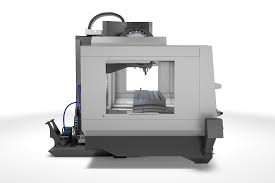

MACHINING

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

CNC Punch Press

Fast punching with enhanced flexibility for varied metal parts.

WELDING

MillerMetal offers in-house Robotic welding, as well as MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

MISC

Miller Metal provides CNC cutting for parts that do not require tight dimensional tolerances.

- About Us

- Contact Us

302-337-2291

302-337-2291

- Services

- 3D CAD Services

- CNC Forming Services

- CNC HD Plasma Cutting Services

- CNC Punching Services

- CNC Machining Services

- CNC Laser Cutting Services

- Tube Laser Cutting Services

- MIG & TIG Welding and Fabrication Services

Laser Cutting

Highlighting our sheet metal processing capabilities are our CNC laser cutters.CNC Forming

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

3D CAD

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

Welding & Fabrication

MillerMetal offers in-house MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Machining

Rounding out our ability to offer turnkey products, MillerMetal offers a wide range of CNC machining services.

CNC HD Plasma Cutting

As an alternative to sheet and plate cutting, Miller Metal offers CNC HD Plasma cutting for parts with non-critical dimensions.

CNC Punching

For years, MillerMetal has offered CNC punching as an affordable way to process sheet metal.

Tube Laser

Our state-of-the art tube laser is on the cutting edge (literally)! Its swiveling head makes easy work out of complex weldment miters and coping.

2 Trumpf TruLaser 5030 Fiber Lasers

The TruLaser 5030 fiber, impress with their high processing speed….

Trumpf TruLaser 5040 Fiber Laser

The TruLaser 5040 fiber, impress with their high processing speed….

- Our Equipment

- CNC Cutting Equipment

- CNC Forming Equipment

- CNC Machining Equipment

- MIG & TIG Welding Equipment

- Miscellaneous Equipment

CNC Cutting

Highlighting our sheet metal processing capabilities are our CNC plasma equipment.

FORMING

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

Lasers

MillerMetal offers high-speed, precision cuts for sheet metal and tubes using advanced CNC laser cutters.

MACHINING

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

CNC Punch Press

Fast punching with enhanced flexibility for varied metal parts.

WELDING

MillerMetal offers in-house Robotic welding, as well as MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

MISC

Miller Metal provides CNC cutting for parts that do not require tight dimensional tolerances.

- About Us

- Contact Us

MillerMetal Fabrication Specialized in Precision Fabrication Across the Mid-Atlantic Region

Thick to thin, using the largest, most versatile, precision equipment available on the market.

MillerMetal manages the logistical chain to maintain high levels of efficiency by decreasing inventory investment and simplifying production control.

MillerMetal Fabrication strives to understand what adds value to the customer.

Our Services

MillerMetal Fabrication manages the logistical chain to maintain high levels of efficiency by decreasing inventory investment and simplifying production control.

Laser Cutting

Highlighting our sheet metal processing capabilities are our CNC laser cutters.

3D CAD

With our CAD capabilities, we are able to turn sketches and prints into 2D or 3D workable parts that can be processed.

Tube Laser

Our state-of-the art tube laser is on the cutting edge (literally)! Its swiveling head makes easy work out of complex weldment miters and coping.

CNC Punching

For years, MillerMetal has offered CNC punching as an affordable way to process sheet metal.

CNC Forming

Whether simple flanges or an intricate transition, Miller Metal offers a diverse ability to form many different types of bends and materials.

CNC HD Plasma Cutting

As an alternative to sheet and plate cutting, Miller Metal offers CNC HD Plasma cutting for parts with non-critical dimensions.

Welding & Fabrication

MillerMetal offers in-house MIG and TIG welding for carbon steel, stainless, aluminum and galvanized applications.

Machining

Rounding out our ability to offer turnkey products, MillerMetal offers a wide range of CNC machining services.

Our Equipment

1 Trumpf TruLaser 5030 Fiber Lasers

BotX Cobot Welding System

Fab-Pak® FHS-B2B

Haas SL20T Lathe

Haas VF-11 Mill – 120″ x 40″

Hexagon Absolute Arm

Why us?

We manage the logistical chain to maintain high levels of efficiency.

Lean manufacturing

Miller Metal embraces LEAN manufacturing techniques with the constant goal of eliminating waste from manufacturing processes and administrative procedures.

Exceptional products

Our ISO 9001:2015 certified quality management aims to continually improve the precision and timeliness of each product that leaves the facility.

Safety

The Delaware Insurance Department awarded Miller Metal for 10 years in the Workplace Health and Safety Incentive Program.

Customer satisfaction

Knowing there is usually a better solution to any given problem has allowed Miller Metal to take on jobs that others would not, turning customers’ ideas into realities.

Before and After of NYC Broadway Subway Station Retrofit by Millermetal

Get in touch

We manage the logistical chain to maintain high levels of efficiency by decreasing inventory investment and simplifying production control.